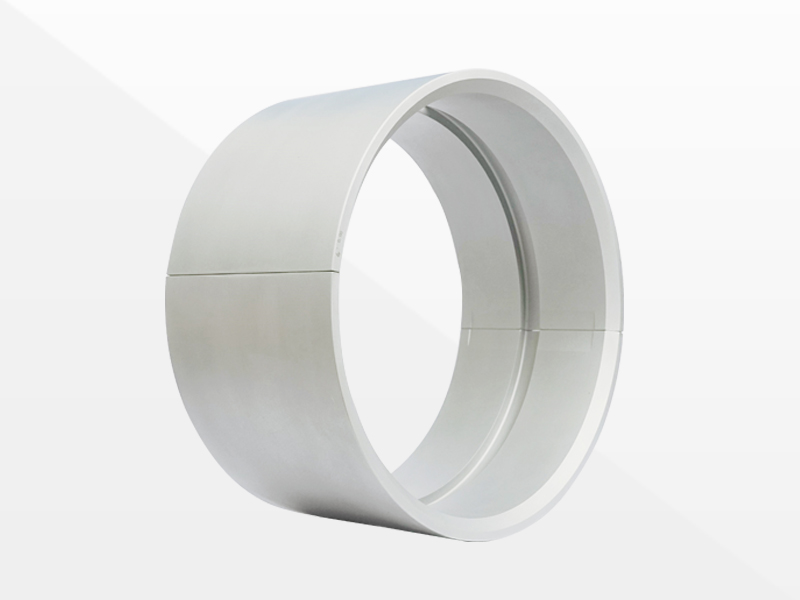

Aluminum-magnesium alloy pain bearing bush shell has high strength, wear resistance, corrosion resistance and good thermal conductivity, because the crankshaft and bearing shell will generate a certain amount of heat during the relative movement, and on the one hand, the heat is consumed by the circulation of lubricating oil, on the other hand, the heat needs to be transmitted to the connecting rod to achieve the purpose of heat dissipation. Compared with Babbitt alloy bearing shingle has higher thermal conductivity, can quickly consume the generated heat conduction, but the journal is required to have higher hardness and smaller surface roughness, bearing clearance is also slightly larger, and has a higher bearing capacity, has been widely used in the internal, aluminum magnesium alloy bearing shingle advantages: Compared with steel-backed babbitt bearing bush, it has light weight, high thermal conductivity, high suitable working temperature, high bearing capacity and high fatigue strength. The double-layer anti-wear structure can protect the external damage of the journal, which is a new product in the field of bearing bush.